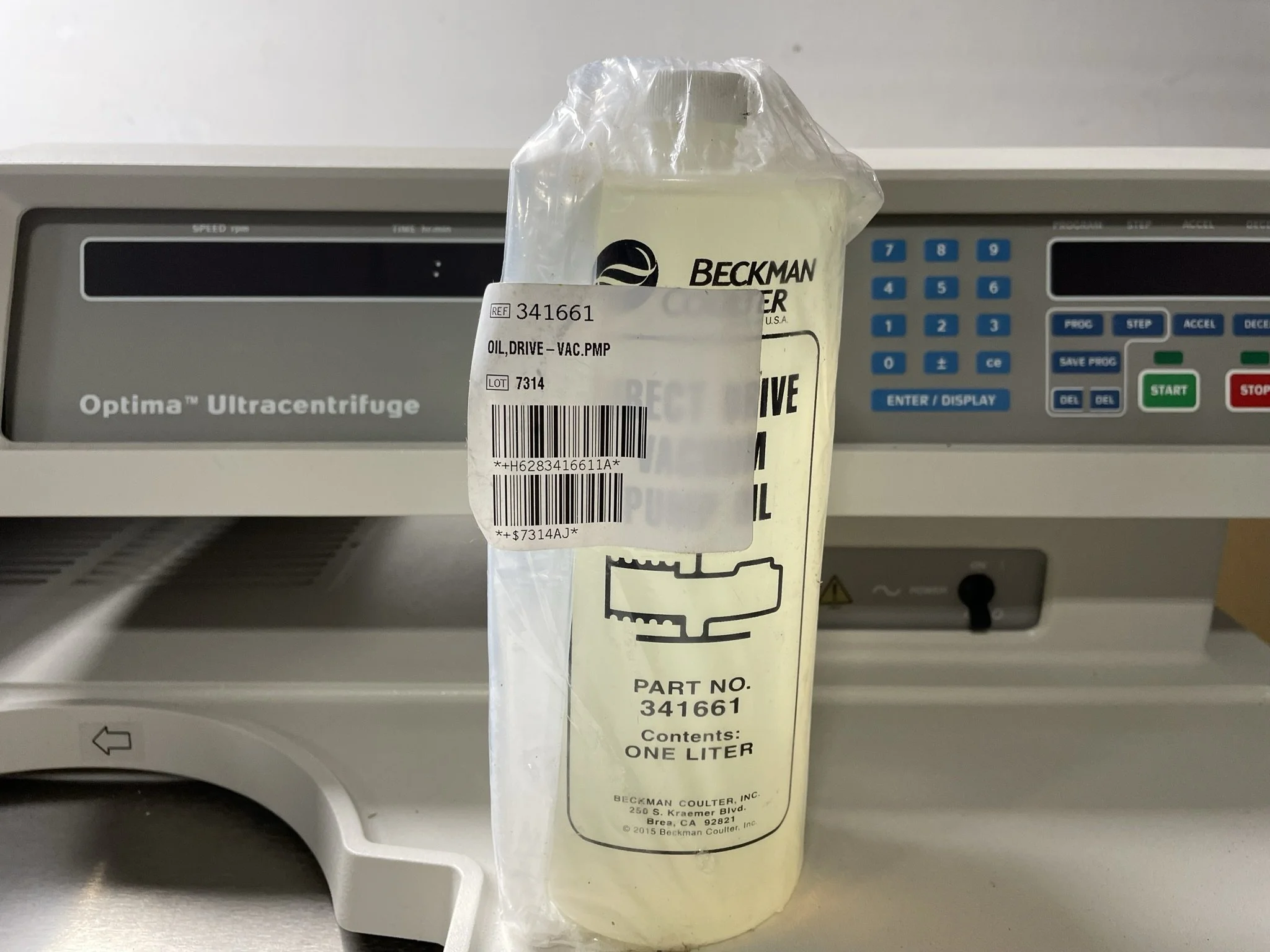

Procedure to change Vacuum Pump Oil used in Beckman Optima ultracentrifuges and Avanti J30I centrifuges

Service AI

Prior to draining the oil, it is always best to operate the vacuum pump until it is at its normal operating temperature of approximately 65ºC.

Always take a test run in the ultracentrifuge with the vacuum pump running to warm up the existing oil. When the pump oil is warm it is less viscous and contaminants will mix with the oil.

Stop the test run. Release vacuum by depressing the "VACUUM" key on the ultracentrifuge keypad, which will stop the vacuum pump and release the vacuum. Turn off power to the instrument and unplug the instrument power cable from the AC Mains.

Disconnect the vacuum pump power cord. Disconnect the vacuum hose from the inlet port. Remove the vacuum pump from the centrifuge. Place the vacuum pump on the flat surface to perform the work.

Remove the exhaust filter. Locate the vacuum pump drain plug. Place the waste oil container under the drain plug. Remove the drain plug. Drain the oil. Always consider and treat the waste oil as hazardous. Hand over the waste oil container to the laboratory safety official at the site for disposal.

Replace the drain plug.

Remove the oil fill plug (normally on top of the pump housing) Add vacuum pump oil until the correct level is reached in the sight-glass. Replace the oil fill plug.

Replace the exhaust filter. It is good practice to always install a new exhaust filter after oil replacement as a part of the preventive maintenance procedure.

Replace the vacuum pump into the centrifuge. Inspect the vacuum pump hose carefully before reconnecting it to the vacuum pump. Replace hose if you observe faults or fine cracks in it.

Reconnect the power cord. Make a test run to verify proper operation of the vacuum pump and centrifuge.

Important tips:

Do not mix hydrocarbon based oils with synthetic oil in vacuum pumps.

Use only “Beckman” Direct Drive Vacuum Pump Oil (Beckman PN. 341661 and Beckman PN. 392760) or oil that is recommended by vacuum pump manufacturer.

website: www.serviceai.us ; email: support@serviceai.us